Obligations to be Followed in Exproof Equipment Selection and Commissioning

Obligations to be Followed in Exproof Equipment Selection and Commissioning

In this article, the steps to be considered in exproof equipment selection and commissioning, as well as the responsibilities of the parties, are discussed in detail.

During the selection and commissioning phase of Exproof products, both the device manufacturer and the end user along with the plant installer company have certain responsibilities to ensure a safe working environment and to meet legal obligations. Compliance with ATEX directives is critically important to ensure the proper use and correct operation of these devices that guarantee safety in explosive atmospheres. Below, the relevant responsibilities are explained in detail.

- Responsibilities of End Users and Plant Installer Companies

The plant installer company is responsible for ensuring a fully ATEX-compliant installation. The device manufacturer cannot directly make product recommendations or usage suggestions. The identification of the working environment and risks belongs entirely to the end user and the plant installer company. The end user is particularly responsible for determining hazardous area classifications including the equipment protection level.

The main responsibilities are as follows:

- Determination of Equipment and Hazardous Area Characteristics: All characteristics of the hazardous environment where the devices will be used must be detailed and classified.

- Prevention of Explosive Atmosphere and Avoidance of Ignition Sources: It is important to prevent the formation of an explosive atmosphere in the hazardous environment and to keep ignition sources away.

- Preparation of Explosion Protection Document (EPD) and Risk Assessment: An Explosion Protection Document must be prepared for the plant, and explosion risks as well as measures against these risks should be evaluated.

- Marking of Hazardous Areas with Warning Signs: Areas with explosive characteristics must be marked with specific warning signs and made conspicuous.

- Classifying the Environment: The environment in which devices will operate must be classified according to factors such as gas, vapor, mist, and dust.

- Analysis of the Device's Intended Use and Impact in the Environment: How the device will affect the specified environment should be analyzed in line with its intended use.

- Responsibilities of the Device Manufacturer

Exproof device manufacturers are obliged to manufacture according to ATEX directives. These responsibilities are important in determining the safety and durability levels of the devices. The main responsibilities of the device manufacturer are listed below:

- Manufacturing According to ATEX Protection Class: Produced devices must be classified according to the ATEX protection class and rated in line with these standards.

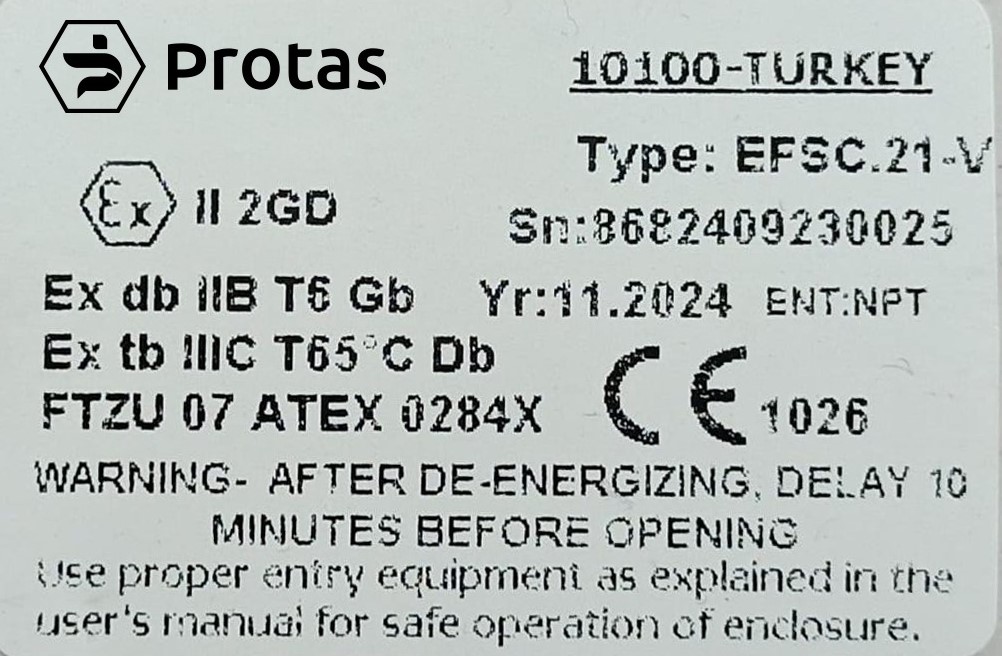

- Proper Labeling: Devices must be marketed with a proper label containing information indicating ATEX compliance. Labeling enables users to understand that the device meets safety standards.

Information Required on the Product Label

Label information required on Exproof devices is very important for product safety and traceability. The manufacturer must include the following information on the product label:

- Manufacturer Name and Logo

- Manufacturer Address

- Product Serial Number

- Manufacture Year

- CE Mark

ATEX Label Information

ATEX-compliant devices must include information related to ATEX on their labels. This information indicates that the device is suitable for use in hazardous areas:

- Ex Logo: Symbolizes that the device is suitable for use in explosive environments.

- ATEX Product Class According to Directives: Indicates which class the device belongs to under ATEX.

- Notified Body Number for Approval: The number of the authorized body approving the product.

Compliance with these responsibilities in the selection and commissioning of Exproof products is vital in ensuring a safe working environment in explosive atmospheres.